I realized I didn’t have some of this information on this site. Since I’m no longer posting on message boards, I figure the information would be better off here.

Here are my posts from the RPF(replica prop forum).

Posted 1/12/11

This is the big one. Not many models come bigger.

I’ve been working on this project for a while.

I thought you guys would like to see my progress.

I’m building the Pilot and Production versions. I’m thinking about making them available as finished models. Kits wouldn’t be very realistic.

These bridges were printed, and still need finishing.

But you guys might want to see more. OK, here is some more.

Deflector dishes in a row, SS, 66″, 350 scale and 18″. I printed the SS dish for reference, the final will be metal.

Some of these parts should look familiar. Even the elusive pink Christmas bulb(well not that elusive).

What I was very happy to find was the original gearmotor.

I can say the warp nacelles are very big.

Very very big, the rectangular blocks are 1″-2″-3″.

You want to know how I did them.

They are particle board, milled to a base shape.

Covered with Bondo and milled again.

These are nearly finished, I just have to mill off the ends. The printed parts are placed for fit.

Want some more…

Here is the neck, about half done.

This is what the part looks like after a few hours of running.

Here is one half of the secondary hull.

It’s big, note the milled surface. It cleans up very quick.

This is what people want to see. This is the upper saucer, it’s done as a 1/4 negative mold to save time and space, the saucer would be about 5 feet in diameter, using traditional methods the molds would be monsters. The ship will be cast in fiberglass.

The sensor bands proved to be problematic. They look great in the pic, but cleaning up the tooling marks were not going so well.

So I’m using an alternate method to save some time and headaches.

I milled groves for the bands, so I can place a 3/8″ round and fill in around it. After I’ve sanded the part smooth.

That’s all for today.

—

Posted 1/13/11

Thanks guys,

CD I’ve never seen that, thanks.

Funny thing I’ve never seen the original ship in person either.

I did have earlier go at the saucer. I did these in 20O8.

This is what made me realize I needed to do something different for the saucer. And I needed to make more room to construct such a model.

Trekman1017 I’m making the second pilot for myself. I designed both pilots so I could make either one.

Clay, sure I will make you one. I don’t feel comfortable giving any particulars at this time. My goal is this year.

I started machining the parts in October.

—

Posted 1/13/11

Here is some more for you guys.

This is how you can make Bondo cake.

Start with a filling of MDF…

Cover with Bondo…

Mill to shape.

Add what I call the “Nubs”, I machined those separately. I’ll show those in another post. I was surprised the fit was so good.

This is the part removed, with some of the nubs set on the deflector ring. I revised the nubs when I realized I would have a heck of a time putting the parts together.

Here is the impulse drive. I had to split it so I could print it. It still needs to be finished as well. Note the change in shape on the right side of the part(just above the ” 24″x36″ “) that’s what I consider to be a tell for an accurate model of the E. Because it’s real easy to miss.

Here is the accelerator and the lower dome(from the primary hull, weapons array?). These were printed as well, I left out the strip in the accelerator. It’s easier to make a piece of styrene to fit than to make a flat printed part flat. The printer works best with organic shapes, but it leaves a very grainy surface which has to be filled and sanded smooth.

CD to answer your questions, I wasn’t planning to put a shuttle bay in the models. Really I never thought of it, I would need to know how far back it goes into the 2nd hull. A shuttle would be 2.75″ long, the Botany Bay @ 4′ long, D-7 @ 8.89′ and BOP @ 5.11′.

To answer the question of display, I was going to mount them high enough to be able to walk under the saucer(I’m 6’3″ so that will tell how high it going to go) and incorporate a circular display cabinet below the models. With the whole thing on industrial casters.

My background is in designing a variety of stuff, from artistic items to machines. Finding the same type of gearmotors used in the spinners(at the front of each nacelles). Was a matter of looking around the surplus sites, and E-bay. This picture was a real help.

It gave a shape and a dimension. Take a measurement across the front of the nacelle, and look for a part with similar specs. Electrically the E is very simple, these motors run on 110 and use a pot to control the speed. I still have to layout the motor mount and how I’m going to place the lights(I know where they go). I’m using the original Christmas lights. I don’t like the look of LEDs on the other E’s I’ve seen. Any ships I sell will have LEDs, I’m only using the the old style of lighting on mine.

Thanks for the offer AD, I had the same idea about a month ago. Using automotive vinyl is far superior to decals and saves a great deal of time on painting. I’ve already created most of the masks, having a 3d model of the subject makes that process a lot easier.

Thanks all for your support.

—

Posted 1/14/11

More updates guys.

Here is the parts for the shuttle bay. The parts are just set in place, to see how well it’s going. I cut off the secondary hull in this manner to simplify assembly.

This is where this technology really shines. I printed the fantail long before I machined the hull, I can’t place the shuttle doors since they are partly inside the 2nd hull.

I used my old nubs to show how this goes together.

Now for the engines, since they are symmetrical I only need to make one.

The bussard mount was printed, and here again is just set in place.

Here it is with the bussard ring in place.

And now to the other end…

The end-caps were printed along with the spacer below it.

Here they are together, with the end-cap ball sitting on top of the 2nd hull.

With the end-cap ball set in place. It likes to slide off so I have to be quick in taking pics. I did it separately to facilitate making the pilot versions.

These parts still have to be cleaned up, which means endless hours of sand and fill, sand and fill, a little paint, sand and fill…

That’s it for today,

—

Posted 1/15/11

Don’t feel stupid, you just don’t know. And thanks for the question.

A lot of people have their own ideas about using this technology. They think it’s point and click, everything just appears by magic. It’s no where near that. To use these tools takes training, experience, and endless trial and error.

Before I can do anything I have to start with a model, namely a model created in the computer. Those start out as drawings in the computer.

This is what started the whole thing for me(please forgive the image quality), These drawings were created by Alan Sinclair(wizardofflight) in Autocad. They were his take on the 11′ Enterprise. In my opinion they are the best that is commonly available(there are better drawings out there, I’ve never seen them, they are something that takes contacts to get. But his are real close, his parts almost match the JK 66″E & the MR E, I have both models and made comparisons to these drawings, I can’t say any of these are 100% accurate. Nor am I making any claims it’s going to be truly accurate, I’m just going by what resources I had access to. So no ultimate claims here).

I then take/modify these drawings to create a 3d model.

But that’s just the beginning of this process. Models such as this are useless in this state. It has to be broken down and simplified for construction. When I do this process I don’t bother with formal drawings, that would be a waste of my time(the only time I do it is with outside contractors).

The next step is to figure out what will be made with what process, and determine the internal structure. This process can take ages, and endless revisions. I can’t tell you how many times I’ve recreated the same parts. It’s like building a house, there will always be surprises along the way.

Once I have an idea of what I want to do, then the fun begins.

Take for instance the 2nd hull.

To get to this stage takes a lot of effort, it’s nothing like how the original was made. The original was a made of balsa planks and turned to shape on a lathe, the original was a one off, the guys that made it were on a budget and a deadline. Nobody cared how they did it, just that it was done on time and below budget.

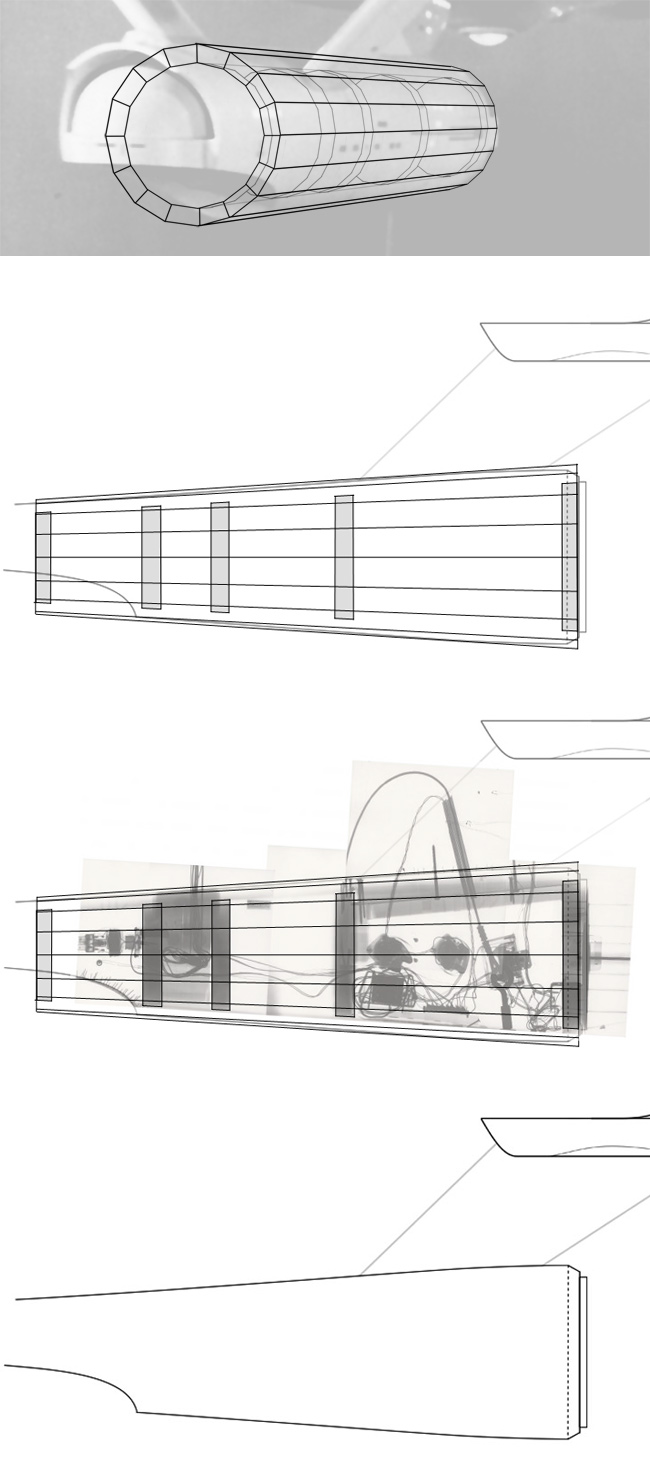

Where is start is with a profile.

This shows the side view of the 2nd hull. Since the hull is circular this makes things easy. Well easier than it could be. From this drawing I layout pieces that make the bulk of the part. I cut out each piece and laminate them to make a general shape of the part.

I then make a rough cut of the part below the final surface.

Here is the final part in RinoCam.

This is a wire frame model, this is what I use to create tool paths(it tells the machine how to move to create the shape of the part). That looks like this…

The software creates a path dividing the part into a series of profiles, in this case they are spaced in .01″ increments. This is(in essence) the same as the traditional method of setting profiles at regular intervals, and filling in between them, then fill & sand to shape. Using machines make that process much more efficient and accurate to the shape desired. BUT, it makes mistakes, and it’s leaves a surface that requires finishing(you can’t just put the part in rubber). If this isn’t modeling I don’t know what is, because I still have to do all of the same stuff I would with a resin model. I still use Dremels and X-acto knives on these parts, plus the sanding seems endless.

This is the part coated with bondo and being milled to shape(this can take several tries, to get right). The final cut for this part took over 30 hours. But the machine doesn’t need to rest, eat or take bathroom breaks.

3D Printing is very similar to milling.

This is my printer(the box to the right is the depowdering station), it is the same as a HP inkjet with a 3rd dimension.

Only it eats print heads at a much faster rate. It uses a powder as a base and prints a section of the part desired with a binder(it makes the powder stick together). Then it drops (.004″) spreads another layer of powder and repeats the process. The software screen looks like this…

This software turns a 3d part into a series of layers. Or sections if you like. The section being printed is displayed on the right. The software controls the printer, this is one of the easiest pieces of software I have ever used. But then what’s doing isn’t that complex. The milling software takes a lot more effort to get right. But then the printer can literally print any shape(withing the realms of physics).

Here is what the work area of my printer looks like…

It doesn’t have a very big capacity. So I have to make parts fit it’s work envelope(8″x10″x8″).

The fun is getting parts out of the machine. They are buried in the powder(and it gets a little messy).

This is the forward part of the Botany Bay(in the printer), scaled to my 66″ Enterprise.

This same model was scaled down to 350 scale and offered from Sovereign Replicas. The patterns were later sold and the same model is offered from Fantastic Plastic. These parts are in the depowder station, where any remaining powder in the parts is cleaned out. I use brushes and an airbrush, the depowder station is connected to a vacuum to catch and collect any airborne powder.

This is the 350 scale model, I’m showing these images to give you guys an idea of how this stuff works. I could literally make this model any scale at will. Saying that makes it sound easy, in some ways it is. But you still have to use modeling techniques after this stage. The surfaces show the striation of the building process, and have a very grainy texture. Plus they are not very strong. The parts are very porous I use CA to soak into the surface to strengthen the part. Then it’s back to traditional modeling again.

I hope this was informative, I’m sure I missed something, so please ask questions.

—

Posted 1/15/11

It’s not a stupid question at all. Like I said I do forget stuff. It isn’t like there are not a lot of steps to this process.

The powder used in the part is done, the powder around the part is used again. The powder is fed from a bin(the rectangle on the left) next to the build area, that powder is spread across the build area(rectangle on the right) with a roller(the polished rod below the black box on the right) , the excess powder is then dumped into a bin(not visible) on the other side of the build area. It can get a bit messy the powder goes everywhere.

I don’t, I guess a thickness of about 1/8″-1/4″ sometimes more. One of the problems of using bondo with this process is it leaves voids on the part. I’ve been getting better at laying up the bondo, but it sill happens.

If you look closely at the part, you will see some of the voids I’m talking about. It’s air gaps, and uncured bondo. That happens, using the methods I’m using it’s inevitable. If it’s bad enough I’ll re-coat the part, and run it again. I guess at my thickness to give myself some some room to run the part again If there are any mistakes. I have much more to show of what else I do to these parts. But I didn’t think to take pics, running these parts is so exciting it’s almost like Christmas morning when I get a part done.

Thanks again guys for your kind words, I better get back to the shop.

—

Posted 1/15/11

I know, I’m one of you. I’m scary to walk around a store with, I know how they made almost everything. And there is no such thing as green manufacturing.

It’s a matter of both. Using a material such as Renshape would be great. But it’s expensive in the sizes I need, and there isn’t a local supplier in Phoenix(I couldn’t find one). The cost of shipping would get a bit prohibitive, and I need material right now. I don’t like to hold up the process a week while parts are being shipped. Then there is the waste, most of the material would be cut out in chunks or end up as dust. Using the method of laminating particle board allows me to create a base part with less waste and cost(and a lot of stability). I use bondo for for similar reasons, I can get it at Wallmart relatively cheaply, and it is very easy to work. I have at least 5 Wallmart’s within a 20 minute drive of my house. My wife likes to joke about, “El Tour De Wallmart”, yea she’s a cyclist.

Bondo can be a pain, and there is much better stuff out there. But the cost outweighs the convenience. Especially when I need a lot of bondo. Using glazing putty and high build primer is a quick and easy way to fill in the pin holes. These method’s were not figured out over a lot of trial and error. When trying to use MDF the surface was fuzzy, that could have been fixed with CA. But it’s a real pain to get smooth, and pricey. Bondo was the next choice for a surface. I stayed with that because each material has tricks to working it. I have ripped off the deck of my router when a cutter hung up on a bit of bondo. It can get pretty strong.

For me speed is most important, I hate to wait for anything. I had a business almost go under because subcontractors had better things to do than make money, and meet deadlines. That’s why I have the equipment I do, I like to get things done.

—

Posted 1/15/11

I designed and built the machine. That’s a long process in itself, I made it with the help of a Bridgeport clone(a manual milling machine).

—

Posted 1/20/11

The low end printers have a long way to go, before they would be considered useful for the general public. People wouldn’t be interested in the machine unless it made items that looked perfect. Those days are coming, but when is anybodies guess.

Here is some more…

I thought you guys would like to see more process. The long two piece part is the accelerator, the one in Al’s documents was way off. That’s understandable it’s not that simple a part. I was really racking my brains as to how to create it.

Here is the original part, sadly it was modified from it’s original state. Why is anybodies guess, most likely to make the SSM follow a set of fan made plans(that’s what some of us think). This is the part I wanted to recreate.

I knew I was going to make the rail down the middle in styrene. So I sized it accordingly, to fit in a center channel. But I still had the problem of the rest of it.

That’s where this tool comes in…

This a 3D scanner, now before people start screaming digital recasting. It’s not that easy(I only wish it was). It scans to a maximum resolution of .004″, an object is placed on a turntable, and the object is traced by a laser. But since it uses a laser there is problems in the laser scattering(the laser sees best with a matte light gray surface, but it still isn’t perfect, I didn’t paint this part). And that effects the scan, which means a lot work on the other end.

Here is what the raw scan looks like…

This was scanned from a part I know is accurate, the reason there is blank spots is the laser couldn’t scan those sections. Because of the part’s orientation in the scanner. I took this file and opened it in Rino…

Above is a rendering of the part in Rino.

Here is the scan data next to profiles that were taken off of the accelerator. In this pic the contours look good, but they are not, and they have to be redrawn, which means things are going to change. Plus this part scan is useless to me, it would not sit on the saucer I machined(not without a lot of modification). Besides I only cared about the part profiles.

My goal was not making an exact reproduction of this part, but to make a new part to match my model. Since the profiles were incomplete I filled in the missing sections.

Here is the completed part in rendered in Rino…

See how it doesn’t look quite right, that’s a remnant of tracing the contours. Really I could care less, because I’m going to fix that in the printed part. All I needed was something to work from. If you look at the printed part it does look a little wonky. It’s nothing that a bit of sanding couldn’t correct. Another thing I did was rescale the part for the model, the part I scanned was about half the size of what I needed. The printed part was split so it would fit in my printer.

Like I said I was only after the part’s contours, I hope I have shown that it isn’t an exact copy of the part. I do not condone recasting, the idea that you can use my scanner to make an exact copy of a part is nearly impossible. I couldn’t get that good a scan off of a part. No matter what I do I still have to recreate what I’m scanning. Which means it’s going to change. I have directly printed parts from my scanner, normally it has very poor results.

To answer the question of where I put these parts. The printed parts are in my modeling room, the routed parts are in my garage(they stand easily on one end). Right now I’m rearranging my garage for this project. Lucky for me my router works on it’s own, so I’m free to get other stuff done.

One other thing, Bondo is really nasty stuff, a router can be a better dust producer than sanding. My machine is contained and I have a exhaust system. Anybody using my techniques use with caution. I can’t take any responsibility for what someone else does.

—

Posted 1/20/11

This is the sort of thing that make projects like this very satisfying.

The parts are taped together to check fit. I set the bussard mount in front to also check fit.

The bench I have it on is a little bowed. I assure you They match.

Why am I showing these now, because I couldn’t stack the parts in this manor before.

Note the stacked pieces of particle board and MDF. One of the tricks I use is to add an extra board under the part. It gives me some breathing room when creating the part. As well as some additional clearance, the reason it’s there is allow a tool I have to cut undercuts around each of the parts.

That gives me an edge to match the parts, But I have to mill off the additional wood below the part line. Sorry I don’t have any pics of this process. I’m sure you guys will get the idea.

These are the molds/jigs for the pylons. Note the rectangles at each end. Those are there to place the 1″x3″ aluminum tube, it gives me a length, and sets the parts in position. The pylons themselves will be made out of fiberglass, since the weight of the nacelle will be carried by the aluminum tube. One other trick I did with these is to mill in the profile that matches the hull and nacelle. Which is the channel between the rectangle and the pylon. When these parts are finished the pylons will bolt into the armature.

I’ll show that when I have the armature done.

This is one of the bussard collectors. It is the pilot version, since it has a flat spot to accommodate the spike. It still has to be finished, I haven’t made up my mind whether to make this one out of fiberglass, or blow mold it, or vacuum form it(I’m leaning toward blow molding). I did drill in an 1/8″ hole in the center since I took the pic. I’m sure you guys will see these molds again.

Now while the router is running, I’m not sitting idle.

I was working on this, the pic looks great. But you can’t see all the pin holes I have to fill. But I did eliminate the tooling marks(groves left by the milling process). It still has a way to go before molding and I still have to add the sensor bands.

That’s all for today.

Remember if you guys have any questions ask away.

—

Posted 2/3/11

Here is another update.

All of the big parts for the E have been machined.

Now for the fun of fitting and finishing the parts.

My router plays a role in this.

The parts are a profile and a cradle for the secondary hull.

I did the same thing for the engine.

here is one half of the hull in the cradle. This makes things easier to handle, and helps to protect the parts. Each of the parts that cradle the hull are a 1/8″ larger than the parts they hold. This allows some room for padding after the hull has been finished.

The cradle that’s more impressive is the nacelle cradle.

It plays a very important roll, since the nacelle is in 4 parts. The parts have to be aligned for mating. Note the steel plate the cradle is sitting on. It’s 3″ thick 2′ wide and 3′ long(it’s about 600 pounds ). It was from a machine I designed that didn’t work, but some of it’s components come in very handy. This plate is precision ground, that means the surface is really flat. Not perfect mind you, but more than enough for model work. The slots in the plate are called T-slots so I can bolt things to the plate. The plate and the cradle work together to help make things straight.

). It was from a machine I designed that didn’t work, but some of it’s components come in very handy. This plate is precision ground, that means the surface is really flat. Not perfect mind you, but more than enough for model work. The slots in the plate are called T-slots so I can bolt things to the plate. The plate and the cradle work together to help make things straight.

I don’t care that the cradle is hanging off each side(besides I couldn’t help it). As far as alignment goes it’s fine. Note the line of MDF between the nacelle half’s. That is what I use to match and eventually mate the parts.

This is what it looks like.

It has a series of holes for pins, each piece of the nacelle has these holes. I use them to align parts in the router, as well as for this purpose. It saves a lot of time, and headaches especially when things go wrong.

The 2 slots in the middle of the template are there so I can route(using a hand router) channels for steel bar to mate the halves(I haven’t done that yet).

Here is a close up. The parts are just set in the cradle, the alignment is very good.

Here is one part of the trick to getting a good alignment.

There are tabs at each end of the cradle. These allow me to place the parts right where I want them, then the template will do the rest.

I did start working on mating the neck to the second hull.

I figured you guys wold like this view. It’s hard to use a camera with one hand, and try to get a good shot.

That’s it for this update, I would have had more done if things were not so cold. Phoenix has been down in the 40’s which makes my garage feel like a meat-locker. For Phoenix that’s really cold, but then to my thin blood anything below 70 degrees is cold. Before I hear people say that’s not cold, keep in mind our summers can get above 120 degrees. It’s all relative.

—

Posted 2/8/11

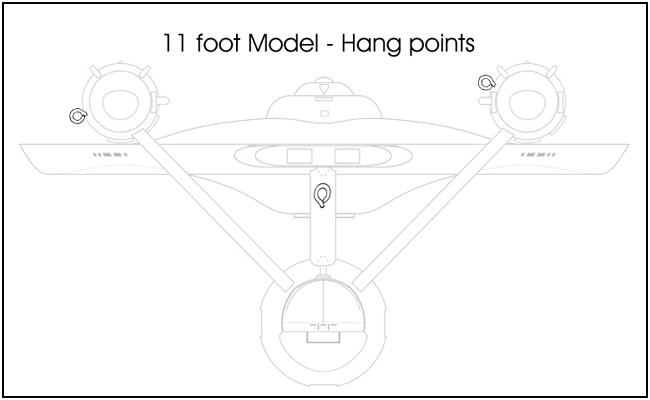

As a friend pointed out, I plan everything. Something which this hobby isn’t known for. I consider this a design project which means I have completed the design before I get to the machining stage. The armature to me is the most important part of the design. You can do almost anything with cosmetics, but a bad structure makes the whole thing a failure. If the model starts to sag in a few years, then it’s a waste of time.

The model is going to be a fiberglass shell with an aluminum armature. On your 66″ your going to need an armature, the 66″ I have has a 1/4″ acrylic armature in the secondary hull and saucer(A 66″ model is a good sized model, even using acrylic may not be enough). The pylons are resin with an aluminum tube cast into place. But they rely on the fiberglass of the secondary hull for support. That’s a real weak spot, because the glassing work on the model is suspect. I have parts changing shape on their own, so even after I complete that model I will be looking for problems.

The structural problems with the TOS E design are complex but not that complex. There are two critical areas on the model.

The white arrows on each end of the model signify gravity. See how far they are from the secondary hull. These cause stress on all of the points I have circled. The primary hull isn’t that hard because it has a lot of room for structure. But the engines pose bigger issues.

The spindly pylons(I think they are a joke) are a problem because they would twist about their base. If you used a weak material without any additional support. Or put too much weight into the nacelles. You’ll eventually have a really warped ship.

You’ll have to do it Steve, or you could do what the other guy did that made a 66″ E, hang it from the ceiling on strings. He’s not going to be very happy with his ships down the road(if he isn’t already).

My pylons are going to be a fiberglass shell, with a 1″x3″ aluminum tube for support. Those are going to bolt into the 1/4″ aluminum armature in the secondary hull. This is where things get interesting.

This shows what I’m doing in section. The pylon support slides into slots milled into aluminum plate. If you’ll notice the rectangular slot in the secondary hull plate. It(there are 4) will slide into corresponding slots in the armature of the 2nd hull. That’s so I don’t have to weld anything, they will just set in place with gravity’s help.

All this why there is box shapes on each side of my pylon patterns.

So the parts will be the correct length, and correctly positioned within the pylons. This structure prohibits a shuttle bay in the model. Since I don’t know how far back it goes into the hull, I’ll bet it would interfere with the model’s structure. As well being able to break down the model should it need to be moved.

I would follow similar rules even with the 350 version of the ship. But that doesn’t mean using metals, but since metals are relatively cheap for such a small model it would be a lot easier to epoxy into place.

I’m doing just that, it will be a ship on a stick. But 1″ the stick is a 1″ steel tube with a 1/2″ center(for electrical). Keep in mind the amount of force required to make the steel bend is so extreme, you could pick up a full size pick-up truck, and the bar will only deflect slightly. That will be going into an aluminum armature.

A cradle is not practical for display purposes and it would pose additional problems(the cradles I made are for matching and finishing purposes), plus it wouldn’t change anything in the structure of the model. And it would have to still have to be anchored to the model. The shell of the model will be supporting very little. It would really detract from the look of the model, as well as having a very awkward base. I have that designed as well, it will be a piece of furniture(on casters). So I can display more things below the model. And keep the model high enough to be able to walk under the primary hull.

Here is a rough sketch of the armature in the 2nd hull.

This is very rough, I’m still working on the details. There are a lot of them. Such as the 1″ slot in the bottom, that will be a tube for the model to set on(with set screws), the wiring will run out of the tube into the hull. It would be impractical to have a connection like the MR E. Since this isn’t a model you can fly around the room.

It does show what I’m thinking, and there is another point of trouble. That is the connection to the primary hull. Other models(the MR E & jk 66″) you cannot remove the primary hull from the second(not without a lot of work). On this model if I couldn’t remove the the primary hull, it would be very impracticable to move(or ship for that matter). I have the solution but that will have be to another post.

Questions? Comments?

—

Posted 1/10/11

Here is the Original E-

The stand it sits on tells me there might be some issues. But it has stood up well. Considering it wasn’t built to last(just through the series photography), nobody expected it to still be around after 47 years.

That solid hull is why the windows below and forward of the pylons were not lit.

Making things solid is not always a good thing. Even solid objects can deform over time(I’ve seen stone columns bowing outward under a load) . It’s best to keep things light as possible, with a structure that has more strength than you would ever need. And in the case of this type of model you need to gain access to the interior. The last thing you want to have to do is rebuild a portion of the model just to change a burned out light.

I’m not worried about the stability of the structure, since I’m using aluminum it would be very stable. Now metals can flex, but since the model will be made of fiberglass. It would be nowhere near the weight that would make the metal flex. Plus fiberglass can be layered up to be very strong(even stronger when bonded to the aluminum) and it only has to support itself. All of this I considered when I was designing the model.

It’s my hope that some of you take this info into consideration with your own builds. Whatever subject they are, I assume you guys are like me. When you build a model you want it to last.

—

Posted 2/10/11

This was posted by Shaw, I’m including it because it’s interesting and on topic.

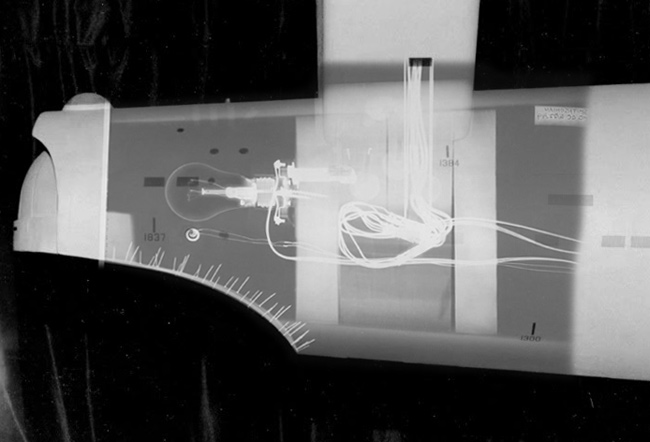

While the supports and dorsal were solid, the secondary hull wasn’t. It was built like a barrel, with open cavities inside. The reason for the lighting being the way it was was because they cut holes in the front and back to access the forward most and rear most cavities. All the wiring between was taped to the outside of the hull until the model was modified to serve as a display piece.

This is approximately what the unturned barrel structure look like…

As for the strength and longevity of the original model, for a good portion of it’s life it was hanging rather than sitting. In that hanging position, the weight of the model was supported via points on the nacelles and the dorsal (though most of the weight was carried by the dorsal point).

Before the model was modified for the second pilot, the model was filmed hanging from a single wire that passed through a channel hole in the dorsal to an anchor point at the bottom the the front cavity of the secondary hull… a point that still exist today (and can be seen in the x-rays of the model).

Of course none of that has any baring on this model project.

But one thing you might consider… the way the original model’s nacelles were built, half the weight of them was originally in the front third of the nacelle. They were almost balanced about the point where the supports attached to the nacelle. So having hollow nacelles might not be enough, you might want to add weight to the front end of them to help keep them true.

—

Posted 2/10/11

More from Shaw at my request.

I have this smaller one (of the aft end) done…

… but I think I have a nice enough side view of secondary hull that I can do the full length x-ray in a little while.

In addition to this, I think the weight balance was thrown off with the removal of the original wooden domes and the hollowing of portions of the front third of the nacelles for the series.

—

Posted 2/12/11

Now I thought the ship was more or less unmolested, before the re-imagining.

Ed did do more to the original model than butcher the paint job. He changed things out right.

Such as-

Now one might say this is minor, but in a purists book this is a big no no.

A part was altered from the original. You can argue people’s theory’s all day, in reality he did what he wanted. The paint job proves it. I’ll bet he was far more happy to be paid for the job, than any love of the E. Model builders in Hollywood are/were not paid all that well. And any boasting rights mean everything, because it means your next paycheck.

In this hobby you can’t take people at their word. Just because it’s published somewhere(especially around this ship). Keep in mind the guys that made this ship looked at it as a job. That job was about 47 years ago, memories can fade even after a few years. The only thing we can rely on is the photographic evidence, and the model itself. But if the model is altered, then things get real murky.

—

Posted 1/12/11

And it’s unnecessary. If he did a straight-up restoration(no access weathering, etc.), and charged the same amount of money. It would have taken less time and he would have walked away with more money in his pocket. Plus it would save having to suffer endless years of grief, from ST fans and model builders alike.

—

Posted 1/12/11

Funny how there isn’t any sign of panel lines on the nacelles, 2nd hull, lower saucer. Thanks Spockboy, I always thought the same thing. The ST exibition that came to Phoenix was very very(I asked for my money back) disappointing.

I see this is your first post Spockboy, welcome to the RPF.

Now another update.

You guys remember me showing you this.

If you remember those slots in the middle.

I routed those out today, and put the nacelle together.

Here is how I did it-

I cut a 1″ steel bar to fit each of the slots(they are 12″ long). I use steel because of its strength, and hopefully it will not flex(it won’t at that length, and the application isn’t strong enough to be any problem).

But I do need to drill holes for screws.

So I use my trusty milling machine.

Pardon the mess, this is a manual milling machine. To some it will look like a drill press on steroids. It does do a whole lot more than drilling holes. It weighs over 2000 pounds, and is precise enough to put my initials on Lincoln’s eyeball(on a penny, I’ll never do it. I can’t see that well ).

).

It’s main job is to use a cutter to shape any material(looks like a drill bit, but it can cut on the side of the bit. They are called endmills, and they come in a variety of shapes and sizes. I use them in router as well. I’ll show more about that as the project progresses). It is an indispensable tool in any machine shop.

For this post I will be using it to drill some holes.

Now in this pic you see a vise(blue thing to the left), a drill chuck w/drill bit(top). Below the drill bit there is a steel bar with holes in it. Now I needed to drill six holes in four bars. Some will think that could take all day. Nope it’s whole lot easier than you think. The first thing I do is mark where I want the holes, I’m not showing that because the holes only need to be close to where I want them. Once I figure where I want them. I put the bar in the vise(tighten down).

Before I drill the hole I do something else.

See that little red box with the shaft on the left side of the vise. It has many uses(I use it hold measuring devices, at times), it has a magnetic base so it can be moved around. In this application I’m using it for a stop. It’s placed at the end of the bar so I can drill holes in the same place on each bar. And since I need holes the same distance from each end of the bar, I just flip the bar over and both sides are taken care of. It really is that easy, and you can do the same trick with a drill press.

Next I place the bars in the slots. The fit is excellent.

Here is one side of the nacelle with the template removed, and the bars screwed into place. The nacelle is now one piece.

Next-

I place a pin at each end. So I can put the nacelle together for sanding/matching.

I placed an end cap on each end of the nacelle. So I can keep things together. It’s notched so the cap is centered.

Here is the Nacelle in one piece. I have started to sand and it will take some work to get everything right. It’s fit is much better than some mainstream kits I have.

That’s it for now, any questions comments?

—

Posted 1/14/11

Here is another satisfying afternoon in the shop.

Again pardon the mess, that’s what happens in my shop. Especially when using hand tools. Most of you know the 2nd hull of the E, I put it together with the same technique as the nacelle.

With one exception, no pins, I had to do the old fashioned way. The parts were off when I machined them, so I couldn’t use the pin trick. That’s more of a convenience, the parts were fine except for that one flaw. So I use the templete to align the 2nd hull to the neck. If you look just to the right of the bars you’ll see some chrome disks. Those are washers I place those in key spots so I can match each side of the 2nd hull. I placed those along the spine and the front of the hull. Then route out the groves for the bars.

Here is without the template, there is a gap between the parts. I’ll fill it in with bondo later, the only thing I had to be careful of was using screws that were to long. The neck isn’t all that deep, I did break through a few times. That’s not a big deal at this stage. Nothing filling and sanding won’t take care of.

I figured you guys would want to see these parts together. If you look in the middle of the image there is a 1-2-3 block there for scale.

Now onto something else you guys might find interesting.

Here is the upper saucer, I ran this part back in October.

I wasn’t entirely satisfied with it(you guys know how that gets). So instead of spending endless hours trying to get it right. I’ll run(machine) the part again. So I have my router place the part’s locator pins(that’s drilling holes). I do that so I know where my origin is(0,0,0 that’s so the router can machine over the original part without cutting into the original surface), and place the part in the machine.

First step-

Re-coat the part with a thin layer of bondo.

Next-

Machine the part, I did what is called a rough cut(at .03″ spacing, it took the machine about 12 hours). It’s the first pass to see how well I coated the part, and to catch any voids and major pin holes. The red marks in the part are voids.

Next-

I fill in the voids and large pin holes with bondo. This time I’m trying something different. Since the part has an endless number of pinholes, I figured I would try glazing the part before the final pass. Just to see what would happen.

Well…

I started running the part this morning, this is what it looked like in the afternoon. All of the red dots are pin holes. Here is is a little closer.

Kind of interesting to see just how many pin holes there are.

My machine is running right now, and it will run well into tomorrow. The final pass I’m running is going to take well over 33 hours to complete. Why? You ask, well I’m running a very fine spacing .01″. That’s one hundred passes for every inch of the upper saucer. The reason I’m doing it so fine is so there is less work later. It means less sanding and (hopefully) less filling in pinholes.

To be continued…

—

Posted 2/17/11

Funny, my shop is in my garage.

The hobbyist CNC market is very well established, and it’s amazing what some of those guys do. It takes a little knowledge, a lot of work, and a great deal of desire.

But if your looking for the easy way to do this stuff. This isn’t it.

Continuation…

I was last machining the upper saucer, things were going well until…

About midway through the job the router drops. Why I have no clue, but it’s cutting below the surface I want.

This happens every now and then(most of the time it goes up), the router will do something like this, then go back to cutting on the original plane. Most likely it’s a software glitch, after all the code to run such a part has hundreds of thousands lines of code. There is bound to be some problems every now and then. Now I don’t consider this a big deal, but it does mean creating a new tool path(this tells the machine where to cut) and reapplying bondo.

When I make a new toolpath, I change it’s spacing. In this case I tell the machine to cut at .02″ spacing, that’s 50 passes per inch. It took less time(about 17 hours).

Things went fine this time. I’m happy with the results. Then comes finishing the part for casting.

I’m sure some of you are asking why I do things this way. The main reason things like this are done is to make the next step easier. The part will take a lot less effort to get smooth than if I made the part by hand.

—

Posted 2/24/11

Sadly that would never happen, most likely Hollywood would never go back to exclusive use of miniatures.

That brings up a question for some of the special effects professionals we have here.

Why did they build such a large model for STTOS?

—

Posted 2/24/11

-Posted by Robn 1-

Keeping it all in focus is the main reason for the model’s size. That requires a strong depth of field, to keep the close end as sharp as the far end. Lens capability dictates the model size. Advances in lens technology allowed smaller models in later years. The Enterprise really wasn’t unusually large for the time. In 2001 the discovery was 54 feet, by the time 2010 was made they could get the same effect with a 12 foot model.

—

Posted 2/24/11

-Posted by Shaw-

And because the 11 foot model wasn’t ready for most of the effects shots for The Cage, we can compare how the 33 inch model looked in camera in 1964 with how the 11 foot model looked in 1965 (making a similar pass)…

—

Posted 3/21/11

Yes, I’m still on it. But it’s at the stage where I’m doing the filling and sanding.

In case you guys haven’t seen these-

Here is the Custom Replicas 66″ nacelle on the studio scale nacelle.

Here is the 66″ upper saucer on the master for the SS upper saucer. This is where I’ve been dividing my modeling time. I’ve been posting it over in the general modeling section. Under the thread-

http://www.therpf.com/f11/custom-rep…-tos-e-110204/

I did have to make a new endcap for the nacelle.

This is the rough stage, the one on the left has been routed to a base shape, the one on the right is just the particle board stacked up.

The one on the left is nearly complete, the one of the right with it’s second coat of bondo.

This is where I have stop with the pics(because I don’t have any more), both parts are the same. I’m going to vacuum form styrene over these parts so it will be easier to attach the corrugated material to them. And save me some time finishing the endcaps.

I’ll post new pics as soon as I have some more progress.

—

Posted 5/5/11

Don’t worry Spockboy, it’s continuing.

I’ve been prototyping the armature.

I made this out of 1/4″ MDF. I did it to experiment with the design. The final will be in aluminum, this is a far less costly way to figure things out.

This is what I’m thinking of doing in the warp nacelle.

These are not finished, I still have a lot to do. Remember these are for prototyping only, the final model will have an aluminum armature.

If you look in the background you’ll see the Big E’s parts everywhere.

I’m fixing those parts so I can wet sand them. Particle board and MDF doesn’t do well when soaked with water. Then it’s back to paint fill and sand.

I’ve been working on other stuff as well, my little E(66″) has been taking a lot of time and frustration. I’m doing stuff to it that will make it a very interesting model.

Plus I’m prepping a blog for these builds for better exposure. I’ll post that when I’m ready, besides most of what I’m putting on it right now you guys have seen. It does need to catch up to this thread.

—

That’s where I left it.

You guys will love this, I since started the whole thing all over again. I got accurate info which made me rethink the whole project. Things are going to get much more interesting from here.